Best Gas Forge for Axe Making: The Ultimate Guide to Propane Forge For Blacksmithing Axe and Knife

When it comes down to axe making, picking the right propane forge is like finding the perfect partner for a dance. It’s not just about the heat; it’s about how well you move together. Stainless steel construction ensures your dance floor doesn’t warp or buckle under the pressure, making those stainless steel forges a sturdy companion in the fiery tango of blacksmithing.

The single burner propane forge stands out for anyone stepping into the world of axe making. Its compact design and efficient fuel consumption make it an easy pick for beginners, without hogging all the space in the shop. Plus, its simplicity doesn’t mean it skimps on power—the flame it throws is plenty for heating steel to the right temperature for shaping.

Choosing the Right Propane Gas Forge for Your Axe Making Needs

Consideration of a propane forge kicks off with understanding what you’re heating. For axe making, which is more heavy-duty than knife making, you want a forge that offers not just heat, but also space even after insulation, so you’ve got room to maneuver. Despite a rating of 0 out of 5, don’t overlook a forge based solely on lack of reviews; functionality for your specific needs, like forge internal dimension and flow of air, holds more weight.

A single burner propane forge, while seemingly humble, boasts an efficiency that is hard to beat. It’s designed for tasks requiring focused heat, such as knife making, but don’t be fooled—it packs enough punch for axe heads too. Plus, it’s propane gas operation ensures a cleaner burn compared to coal, reducing your shop’s footprint on the environment.

The Importance of Forge Design

Getting into the nitty-gritty, forge design isn’t just about aesthetics—it’s about how the thing works. A well-designed propane forge focuses on efficient fuel consumption, ensuring the heat is right where you need it. The flow of air through the burner can make or break the temperature control, which is crucial when working with steel for axe making.

Stainless steel becomes the material of choice not just for its robustness against the blaze, but also for its ability to withstand the test of time. A single burner propane forge, equipped with a reliable burner, proves that sometimes, simplicity leads to the most efficient outcomes. And who can forget the importance of an even heat distribution? It ensures every part of the blade receives the love and attention it deserves.

Fine-Tuned Burner Control

Speaking of heat, fine-tuned burner control is like the volume knob on your favorite stereo. It allows the blacksmith to dial in the perfect temperature, ensuring the steel is neither too hot nor too cold. This level of control is vital, as it directly impacts fuel consumption—too much gas, and you’re wasting money; too little, and your steel won’t get hot enough.

The relationship between fuel consumption and control cannot be overstated. A gas forge that offers adjustable output ensures that the user can achieve the temperature needed for forge welding without breaking the bank on propane gas. It’s all about finding that sweet spot where efficiency meets efficacy.

Secured Connection for Safety

Safety in the workshop is non-negotiable, especially when dealing with fire and high temperatures. A secured connection for your propane forge ensures that the fuel supply is reliable and leak-free, preventing potential hazards. It’s the peace of mind every blacksmith or hobbyist needs when the focus is on crafting, not on worrying about the propane tank.

Regular checks and maintenance of hose connections can stave off disaster, making sure that the flow of propane is controlled and consistent. This not only aids in maintaining a safe environment but also contributes to the forge’s efficiency, ensuring that the flame is steady and the temperature constant. A secure setup means more time forging and less time fiddling with equipment.

Single vs. Multiple Burner Forges

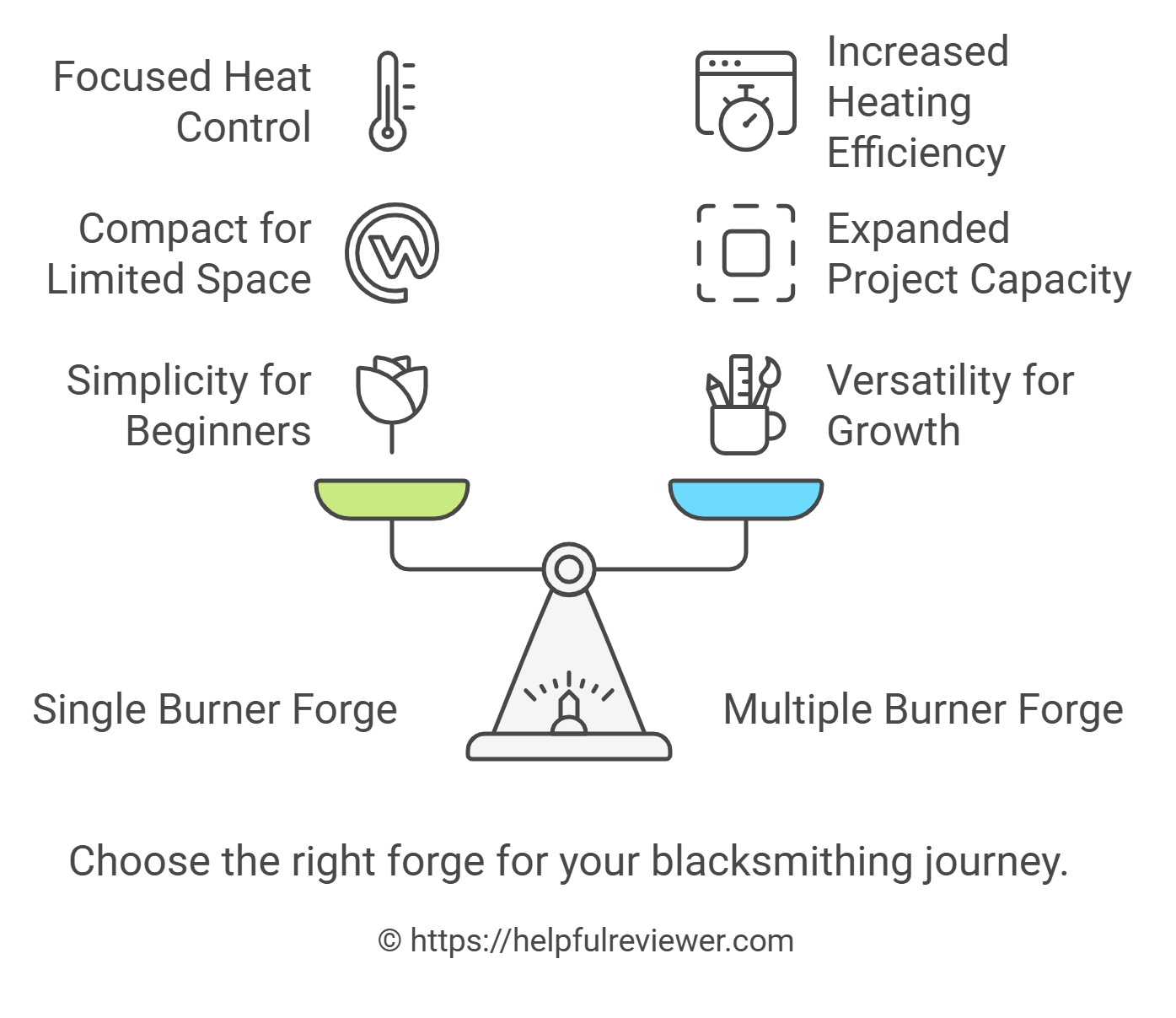

Choosing between a single and a multiple burner propane forge comes down to what you’re looking to create. For those just dipping their toes into the world of blacksmithing with projects like knife or axe making, a single burner offers simplicity and focus. It heats quickly and efficiently, making it less daunting for beginners.

However, as one’s skills grow and projects expand in size and complexity, the allure of a multiple burner forge becomes undeniable. The ability to heat larger or multiple pieces of metal simultaneously opens up new possibilities in craft and efficiency. Think of it as upgrading from a solo act to a full band—each burner plays its part, allowing for greater versatility in your blacksmithing projects.

Benefits of a Single Burner for Beginners

Starting with a single burner propane forge introduces the beginner to the craft without overwhelming them. Propane gas forges are easy to manage in terms of heat control and fuel consumption, making them ideal for focusing on individual projects like knives or the heads of axes.

Not to mention, the compact nature of a single burner does wonders for those with limited shop space. It’s an efficient, no-fuss tool that allows newcomers to learn the ropes of metal heating, without necessitating a large initial investment. Plus, the satisfaction of mastering a single flame before moving on to more complex setups is unmatched.

When to Upgrade to a Multiple Burner Forge

Graduating to a multiple burner forge marks a turning point in a blacksmith’s journey. When time efficiency and the ability to handle larger or multiple projects become a priority, additional burners provide the flexibility needed to spread one’s creative wings.

The decision to upgrade often comes naturally as one’s ambition and the scope of projects grow. If you find yourself consistently pushing the limits of your single burner, longing for more space or faster heating times, it’s probably a sign you’re ready for the next step. Embrace the change—more burners mean more opportunities to sculpt metal into art.

Top Picks: Best Gas Forges for Axe Making Review

Finding the right gas forge for axe making is a big deal. Whether you’re a hobbyist or a seasoned blacksmith, the forge you choose can make or break your axe-making game. It’s like finding the perfect pair of shoes; you need them to fit, last, and not break the bank. Let’s dive into the top picks that have been heating up the forge market.

1. Whisper Deluxe Gas Forge by NC Tool Co – Best Overall Gas forge

The Whisper Deluxe Gas Forge by NC Tool Co brings the heat with its double burner setup. It’s like having a twin-engine jet at your disposal, ready to forge steel into your next masterpiece. The forge comes equipped with a stainless steel door, making it both sleek and durable. Hose, regulator, and gauge are included, ensuring you have everything to get started. Right out of the box, it’s set to become the workhorse of your shop.

Pros and Cons of This Model

On the plus side, this forge is a marvel in temperature control and space. It heats up faster than you can say “anvil,” and the dual burners offer versatility in heat management. The downside? It’s a bit like owning a sports car; the fuel consumption can get high, and the initial investment is not for the faint of heart. But, for serious axe makers, it’s a solid choice.

2. Atlas Single Burner Knifemakers Forge – Best Runner up Gas Forge

The Atlas Single Burner Knifemakers Forge is the definition of efficiency. Described as the best forge for bladesmithing, it’s a gem for those starting in the craft of axe making. With dimensions that are compact yet capable, it boasts firebox dimensions that promise high heat and less propane use. Talk about getting more bang for your buck. This forge makes heating and hammering out your blade shapes easier than pie.

Why It’s Suited for Axe Making

For axe making, gas forges like the Atlas are a dream. The single burner is more than capable of reaching the scorching temperatures needed for forging. Due to its efficient design, it uses fuel sparingly, keeping costs down. And with its firebox dimensions, the Atlas Forge accommodates axe heads and blades with ease, making it a top pick for both beginners and seasoned smiths.

3. Atkrou Two Burner Double Door Knifemaker Economy – Best Double Door Gas Forge

The Atkrou Two Burner Double Door Knifemaker Economy Forge is the right tool for blacksmiths who mean business. It’s like bringing a tank to a knife fight. The double doors swing wide, welcoming larger projects with a warm blast. Having two burners offers a symphony of heat, ensuring your steel is evenly kissed by flames. It’s the beefy companion you want when heavy lifting is on the agenda.

Highlights and Potential Drawbacks

This forge’s dual burners and spacious chamber accommodate a wide range of projects, from delicate knives to robust axes. The efficiency of heat distribution means less time getting your metal work-ready. However, it’s essential to note that with great power comes great propane usage. This forge might make your propane tank weep, but for the quality and capacity it offers, many find it a worthy trade-off.

4. Vevor Portable 2 Burner Propane Forge, 2600°F Metal – Best Knife Blacksmithing Forges

The Vevor Portable 2 Burner Propane Forge is like the Swiss Army knife of forges. Don’t let the word “mini” fool you; this forge packs a punch with its 2600°F heat capability. It’s the all-in-one kit for the blacksmith or farrier on the move, offering a portable solution without compromising on power. Made from polished stainless steel with a ceramic fiber blanket for insulation, it promises durability and high performance.

Whether you are setting up shop in a grand space or working out of your garage, this forge brings versatility and efficiency to the table. The dual burners offer optimal heat control, making it easier to work with different types of metals and projects. For those looking to combine portability with power, the Vevor Portable 2 Burner Forge is a heavyweight contender in a compact frame.

Ideal Forge for Small Workshops

The Vevor Portable 2 Burner Propane Forge is just what a small workshop needs. It’s compact and doesn’t take up a ton of space, making it perfect for those tight on room. With its portable design, moving it around is a breeze, ensuring your small workspace remains flexible and adaptable. This forge heats up quickly, thanks to its efficient burners, allowing you to get to work without waiting ages for the metal to reach the right temperature.

What’s more, it’s got a large capacity that defies its compact size, offering ample space for various blacksmithing projects beyond knife making. Despite its smaller footprint, this forge doesn’t compromise on power or efficiency – a match made in heaven for hobbyists or professionals operating in smaller setups.

5. DEVIL-FORGE Gas Propane Forge DFPROF3+2D, 3 Burners DFP (240.000 BTU) use 1, 2 or 3, Gas Ball Valve, Air Choke, 2 Doors, Knife Making, Blacksmith, Farrier, 2500°F / 1370°C

The DEVIL-FORGE Gas Propane Forge DFPROF3+2D is a powerhouse, sporting three burners that can be used one, two, or all three at a time, providing unparalleled flexibility. Its gas ball valve and air choke offer fine-tuned control over the flame, ensuring that blacksmiths and farriers can achieve the precise heat needed for their craft. With an impressive maximum temperature of 2500°F, this forge is up for any challenge.

Its double-door design allows for easy access and manipulation of longer pieces, making it especially suited for axe making. The sturdy construction, including a durable stainless steel build and efficient insulation, guarantees this forge can handle repeated use, making it a reliable choice for professionals looking to elevate their work.

The Choice for Professional Axe Makers

Professional axe makers need a forge that can keep up with their demands, and the DEVIL-FORGE DFPROF3+2D is exactly that. This forge offers a trio of burners that dish out an impressive 240.000 BTU, granting the intense heat necessary for high-quality axe crafting. The option to use one, two, or all three burners allows craftspeople to adjust the forge to the precise needs of each project.

Additionally, the inclusion of two doors enables the handling of axes and other large pieces with ease, providing both versatility and efficiency in a professional setting. This forge not only meets the expectations but often surpasses them, positioning itself as the go-to tool for ambitious blacksmiths and knife makers alike.

6. Simond Blacksmiths Single Burner Propane Forge – Best efficiency

For simplicity and effectiveness, the Simond Blacksmiths Single Burner Propane Forge stands out. It’s designed specifically with efficiency in mind, utilizing a single propane gas burner to produce a concentrated heat source suitable for a variety of blacksmithing and knife-making projects. Its compact size belies its power, making it an excellent choice for those starting out in the crafting world or with limited workshop space.

Equipped with a durable steel construction and effective insulation, this forge maintains high temperatures while minimizing fuel consumption. The design ensures quick heating, making it perfect for those who value both time and quality in their forge work. It’s an affordable, reliable option for hobbyists and professionals alike.

With Stand for Knifemaking Farriers

The design and functionality of the Simond Blacksmiths Single Burner Propane Forge are further enhanced with the addition of a sturdy stand. This feature provides a stable base for knife making, farriery, and other metalworking crafts, ensuring safe and efficient operations. The stand not only elevates the forge to a convenient working height but also enhances its portability, making it easy to set up wherever work needs to be done.

Whether in a professional shop or a home garage, this forge with its stand proves to be an invaluable tool for farriers and knife makers. It’s a testament to how specialized equipment can make all the difference in producing quality work, offering a blend of practicality and performance for the craftsman.

Getting the Most Out of a Gas Propane Forge for a Good Blacksmith

To maximize the potential of your gas forge, regular maintenance and proper operational practices are key. Keeping your forge clean, checking for leaks, and ensuring all connections are secure can significantly extend its life and enhance performance. Proper usage not only ensures the longevity of the forge but also maintains a safe working environment.

Understanding how to efficiently manage fuel consumption can also lead to better heat control and lower operating costs. By regularly inspecting and adjusting your forge, you can achieve the perfect balance of temperature and fuel efficiency required for high-quality blacksmithing and knife making.

Proper Maintenance Tips of a Blacksmith Forge

Keeping your gas forge in top condition means dedicating some time to its upkeep. Regularly clearing out ash and debris from the chamber, inspecting the burner for clogs, and ensuring the propane tank and hoses are in good condition are fundamental practices. Using a forge with care and attentiveness not only prolongs its life but also prevents potential hazards.

Furthermore, applying a refractory coating to the interior can help protect against wear and tear, keeping the heat where it belongs – inside the forge. These simple yet effective maintenance steps are crucial for anyone looking to get the most out of their gas forge.

Extending the Life of Your Forge

To extend the life of your gas forge, it’s important to give attention to both its physical condition and how it’s used. Using the correct fuel, managing the interior temperature to avoid overheating, and shutting down the forge properly after use are essential practices. Proper maintenance not only guarantees the forge’s longevity but also its reliability and efficiency in heating metal to the right temperatures for forging and welding.

Investing time in learning about your forge, from the ideal fuel pressure to the best way to clean its components, pays off in the long run. With the right care, a gas forge can serve as a dependable partner in blacksmithing, knife making, and other metal crafts for years to come.

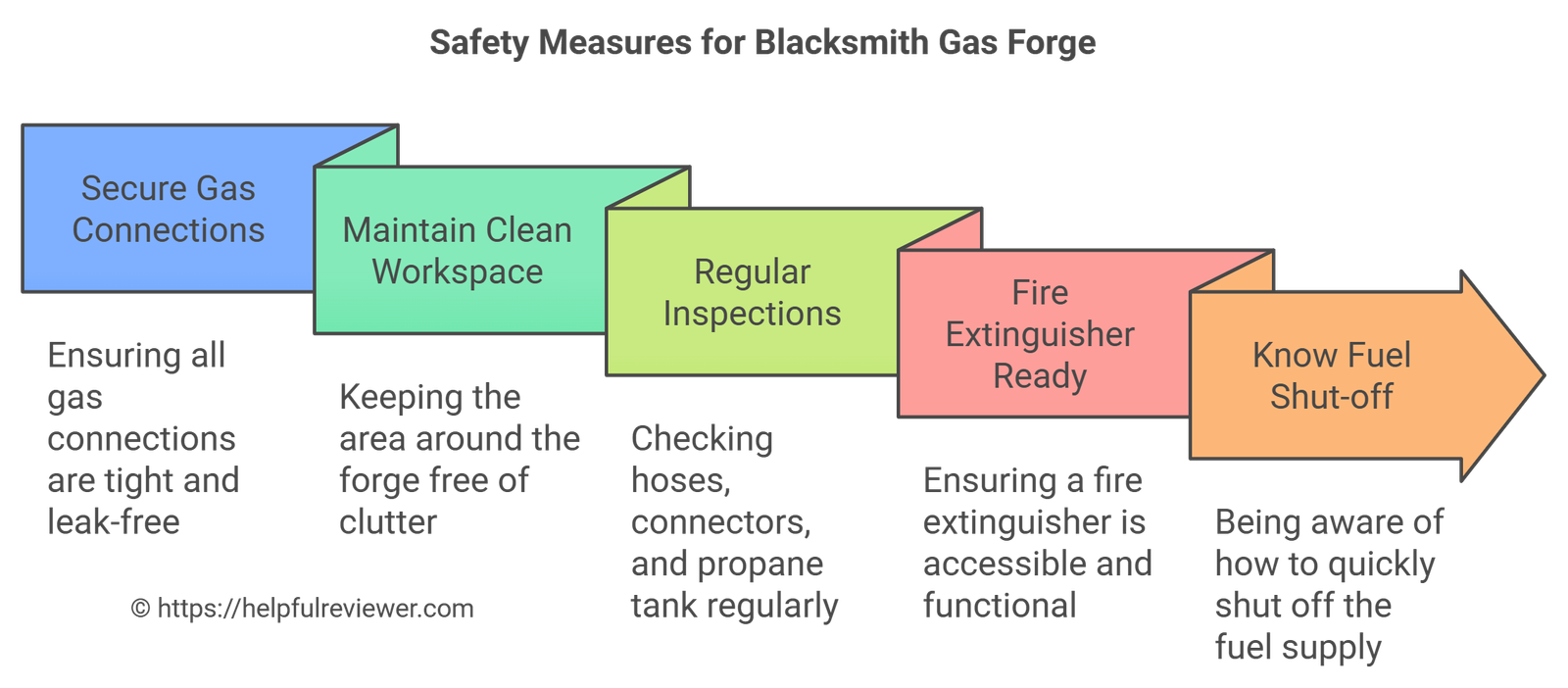

Safety Measures to Consider When Using a Blacksmith Gas Forge

When dabbling in axe making, ensuring a safe forge setup isn’t just smart; it’s essential. From securing all gas connections to maintaining a clean area around the forge, safety measures are the backbone of any successful forging endeavor. A gas leak or a cluttered workspace can lead to accidents faster than steel can heat in the forge. So, whether it’s a hobbyist striking the hammer or a seasoned smith, safety protocols must never be glossed over.

Regular inspections of hoses, connectors, and the propane tank can prevent hazardous situations. Moreover, having a fire extinguisher handy and knowing how to shut off the fuel supply swiftly can make a substantial difference in an emergency. It’s about making forging a joy, not a hazard.

Ensuring a Safe Forging Environment when using a forge that is hotter than other

A safe forging environment is not just about the right equipment; it’s also about how you use it. Proper ventilation, for instance, is crucial to avoid inhaling harmful gases. Similarly, using protective gear such as gloves, goggles, and aprons can safeguard against burns and injuries. It’s like putting on armor before heading into battle—necessary and non-negotiable.

Additionally, understanding the properties of the materials you work with goes a long way in preventing accidents. Steel, when heated, can be unpredictable. Hence, knowledge of metal’s behavior at high temperatures, combined with strict adherence to safety measures, creates a forging environment that’s as safe as it’s productive.

Final Verdict: Selecting the Best Gas Forge

Selecting the best gas forge for axe making boils down to a few key factors: efficiency, durability, and design suitability for the task at hand. With various models offering unique benefits from single to multiple burners, the final choice largely depends on specific crafting needs and workshop size. It’s about finding a balance between what’s desired and what’s required—no one size fits all here.

While beginners might lean towards smaller, single-burner forges for their manageability, professionals may opt for more robust, multi-burner options. The critical takeaway is to choose a gas forge that not only fits the budget but also encourages skill development and creativity in axe making. In the end, the best forge is the one that becomes a smith’s true companion, echoing their dedication to the craft with every heat cycle.

Balancing Price and Performance

Embarking on the journey of selecting the right forge often brings one to a familiar crossroads: balancing price with performance. It’s like choosing between a reliable sedan and a high-powered sports car; both have their merits, but one might suit your lifestyle better. A high-end forge might offer incredible heat and efficiency, but could it be overkill for a novice? On the flip side, starter forges, while budget-friendly, might not hold up under the demands of extensive, heavy use.

The secret lies in identifying what you need versus what you want. A durable, well-designed forge that delivers consistent heat without breaking the bank is often the sweet spot for many. Remember, the true cost of a forge isn’t just its price tag—it’s also in how much it can enhance the quality and efficiency of your craftsmanship over time.

Making an Informed Decision for Your Crafting Needs

Deciding on gas forges calls for a mix of research, understanding one’s crafting goals, and sometimes a bit of trial and error. Reading reviews, watching tutorials, and, if possible, hands-on testing can unveil nuances about gas forges that specs sheets can’t capture. Remember, a forge might tick all the boxes on paper but still not feel right when you’re standing in front of it, hammer in hand, ready to work.

That said, balancing desires with practical needs means finding a forge that grows as you do. Whether it’s starting with a single burner and dreaming of a day when a 3-burner forge will be on the shop floor, or selecting a model known for its efficiency and reliability, the informed decision comes from weighing options against one’s aspirations and workshop realities, not from impulse buys. Good choices come from good information, and that’s as true for forges as it is for any tool in the shop.

They say wisdom is found in a multitude of counsel, and when it comes to gas forges for axe making, shared experiences are invaluable. Collaborating with peers, whether through forums, workshops, or local blacksmithing communities, can deepen understanding and appreciation for the craft. It’s about building a collective knowledge base that benefits all, from the novice to the master blacksmith.

Sharing tips on maintenance, fuel efficiency, or even innovative forging techniques can transform solo endeavors into a journey enjoyed by a fellowship of crafters. Encouraging each other, solving problems together, and celebrating successes builds not just better blacksmiths but a stronger blacksmithing community.

Community Insights on Gas Forges

When it comes to gas forges, the collective wisdom of the blacksmithing community is a treasure trove of insights. From recommendations on the best forges for beginners to nuanced discussions about the merits of different burner designs, engaging with community insights can significantly enhance one’s understanding and approach to axe making.

It’s one thing to read a spec sheet, but hearing firsthand about a fellow smith’s experience with a particular forge model can paint a far more accurate picture. These insights can steer newcomers away from common pitfalls and encourage seasoned artisans to experiment with new techniques or tools they hadn’t considered. In essence, the community’s collective wisdom propels the craft forward, one shared story at a time.

Why Peer Recommendations Matter

Peer recommendations carry a weight that advertising simply cannot replicate. When a fellow blacksmith endorses a gas forge, it comes with an understanding of the needs, challenges, and joys that come with the craft. It’s advice grounded in practical, real-world experience, not marketing speak. Such recommendations can guide informed decisions, providing comfort that the selected forge has already proven its mettle in the fire of actual use.

This trust in peer recommendations underscores the value of the blacksmithing community as a reliable resource. It creates a culture where wisdom, not just information, is shared; where advice is given not just to promote a product but to uphold the traditions and standards of the craft—a testament to the brotherhood and sisterhood of blacksmiths worldwide.

Forging Ahead: Your Next Steps in Axe Making

Now that you’ve got a handle on the best gas forges for axe making, taking your craft to the next level requires a solid game plan. Whether you’re a metal hobbyist looking for a weekend project or aiming to become the next legendary bladesmith, focusing on honing your skills is crucial. The journey from raw steel to a polished axe head is both art and science. By selecting the right tools, like a durable propane forge with precise temperature control, you’re laying the groundwork for success. Remember, every great blacksmith started with a single hammer strike.

As you venture further into the world of blacksmithing, consider expanding your workshop to include a variety of forges or tools that cater to different aspects of the craft. Explore techniques like forge welding, get your hands on various types of steel, and don’t shy away from projects that challenge your skills. Joining a community or a forum can provide invaluable feedback, stir up inspiration, and offer a treasure trove of knowledge from folks who’ve been where you are now. Your next steps in axe making are not just about mastering the fire or the metal but also about embracing the journey of continuous learning and improvement.

FAQ on the best gas forge

Q: What brand forge do they use on Forged in Fire?

A: The show “Forged in Fire” often uses forges from brands like Majestic and other custom makers. These forges are designed for high efficiency and versatility in blacksmithing.

Q: What is the best type of blacksmith forge?

A: The best type of blacksmith forge depends on your needs. Propane forges are popular for their ease of use and portability, while coal forges are favored for traditional techniques. Each has its advantages depending on the projects you undertake.

Q: What fuel is best for a forge?

A: Propane is often considered the best fuel for a modern blacksmith forge due to its efficiency and ability to reach high temperatures quickly. However, some blacksmiths prefer coal for its traditional use and the unique characteristics it can impart to the metal.

Q: What psi should a propane forge be?

A: Most propane forges operate efficiently at a pressure of around 2 to 5 psi. It’s essential to adjust the psi based on your specific forge’s design and the desired flame characteristics.

Q: What metal do they use in Forged in Fire?

A: On “Forged in Fire,” the contestants typically use high-carbon steels for their blades, as these materials can achieve the hardness and edge retention necessary for quality knives and tools.

Q: What power hammer is used on Forged in Fire?

A: “Forged in Fire” contestants often use various power hammers, but one commonly seen is the 50-pound Little Giant hammer. This hammer allows for efficient shaping and forging of metal.

Q: What is the best material for a blacksmith?

A: The best materials for blacksmithing include high-carbon steel and Damascus steel for blades. For tools and structural work, mild steel is often preferred due to its workability and lower cost.

Q: How much does a gas forge cost?

A: The cost of a gas forge can vary widely, typically ranging from $200 to $1,500, depending on the brand, size, and features. Entry-level models are cheaper, while professional-grade forges can be more expensive.

Q: Are gas forges good for beginners?

A: Yes, gas forges are great for beginners. They are easy to use, require less setup than coal forges, and provide consistent heat, making them ideal for those just starting in blacksmithing.

Q: What safety precautions should I take when using a propane forge?

A: When using a propane forge, always ensure proper ventilation, wear appropriate safety gear, including gloves and goggles, and have a fire extinguisher on hand. Always follow the manufacturer’s instructions for safe operation and maintenance.